July – 2025

Achieving a high-quality surface finish in cylindrical and internal grinding is essential for producing precision components, especially in industries where tight tolerances and superior aesthetics are required. Whether you’re working with hardened steels, carbide, or other difficult-to-machine materials, the right combination of wheel selection, machine setup, and process control can significantly enhance surface finish and part quality.

At Elitech Machine Tools, we understand the critical parameters that influence grinding performance. This guide covers key aspects to help you consistently achieve excellent surface finishes in OD (Outer Diameter) and ID (Internal Diameter) grinding operations.

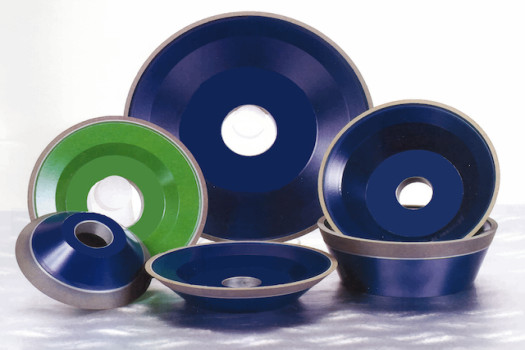

1. Grinding Wheel Selection and Dressing

Abrasive Type & Grit Size

Selecting the correct abrasive type—such as aluminum oxide, CBN (Cubic Boron Nitride), or diamond—is foundational. Finer grit wheels (e.g., 80–120 grit) generally produce smoother finishes but may require slower feed rates.

Bond Type

Choose the right bond (vitrified, resinoid, etc.) based on your material and application. Vitrified bonds are preferred for precision applications due to their rigidity and thermal stability.

Wheel Dressing

Regular wheel dressing prevents glazing and ensures consistent cutting action. To refine the wheel surface and improve finish:

-

Slow down the dress traverse speed.

-

Reduce the depth of dressing.

-

Maintain proper dressing overlap ratio to ensure even wheel conditioning.

2. Optimizing Grinding Parameters

Fine-tuning operational parameters is often the quickest route to better finishes.

Wheel Speed

Increase the wheel speed cautiously (within MOS limits). This reduces chip thickness and improves surface smoothness.

Feed Rate & Depth of Cut

-

Reduce feed rate and depth of cut during finishing passes.

-

Avoid overly light cuts that can dull the wheel and cause thermal damage.

Spark-Out & Dwell Time

In OD and ID grinding, increasing spark-out or dwell time allows the wheel to “polish” the surface by removing fine irregularities.

Workpiece Speed & Oscillation

-

In ID grinding, lower workpiece RPM while maintaining depth per revolution.

-

Apply oscillation in plunge ID grinding to distribute heat and improve finish.

3. Coolant Application and Filtration

Coolant plays a major role in surface finish and tool life.

Coolant Flow & Pressure

Ensure adequate flow to the grinding zone. Aim the coolant precisely to flush chips away and control heat buildup.

Coolant Filtration

Poor filtration reintroduces particles that scratch the surface. Use filters that remove particles smaller than 10% of the wheel grit size.

Coolant Type

High-lubricity synthetic or straight oil coolants improve finish by reducing wheel wear and thermal damage.

4. Machine Condition and Setup

The condition of your grinding machine directly affects surface finish quality.

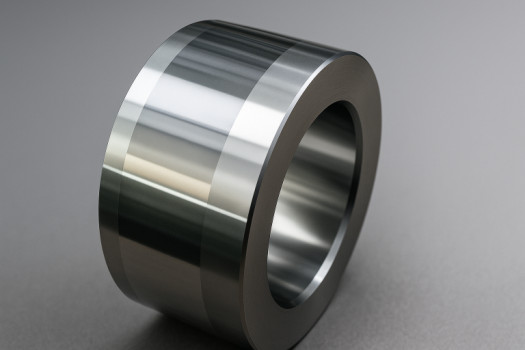

Wheel Balancing

Unbalanced wheels cause vibration and chatter. Use static, dynamic, or auto-balancing systems to maintain smooth operation.

Machine Stiffness

Loose spindle bearings, worn slides, or unstable fixtures reduce accuracy. Regular maintenance and vibration analysis are crucial.

Workpiece Alignment

Ensure the workpiece is aligned with centers and clamping devices are secure. Even slight misalignment can degrade surface finish.

5. Additional Best Practices

-

Use scrubber nozzles in OD or surface grinding to clean chips from wheel structure (not ideal for ID grinding).

-

Train operators to recognize early signs of poor finish (e.g., chatter, scratches) and make real-time corrections.

-

Pre-grind surface preparation (e.g., turning or milling) should avoid deep marks that would require excessive grinding to correct.

Final Thoughts

Improving surface finish in cylindrical and internal grinding is not about a single fix—it’s about optimizing a combination of factors. From selecting the right grinding wheel to maintaining the machine and adjusting parameters, each step contributes to consistent, high-quality results.

At Elitech Machine Tools, our CNC cylindrical and internal grinding machines are engineered for precision, stability, and ease of adjustment—helping you achieve the surface quality your applications demand.

Have a specific grinding challenge? Contact our team today—we’re here to help you optimize your grinding process.