April – 2025

Understanding CBN and Diamond Grinding Wheels: Choosing the Right Abrasive for Your Application

At Elitech Machine Tools, we are committed to helping our customers achieve the highest standards in grinding efficiency, precision, and surface finish. A key factor in optimizing grinding operations is selecting the right grinding wheel material — especially when working with hard metals and advanced materials.

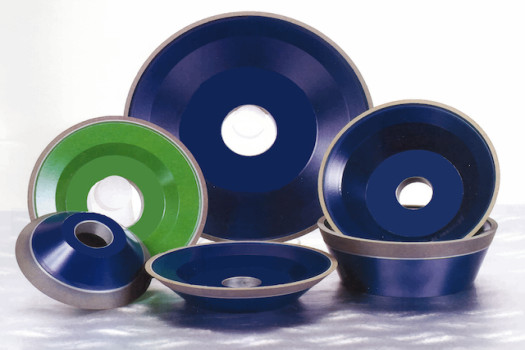

Two of the most advanced abrasives used today are CBN (Cubic Boron Nitride) wheels and Diamond wheels. Though they may appear similar, they serve distinctly different applications based on their properties and performance.

CBN Wheels: Engineered for Ferrous Materials

CBN wheels are exceptionally effective when it comes to grinding ferrous materials such as:

-

High-speed steel

-

Tool steel

-

Cast iron

-

Nickel alloys

-

Stellite

CBN is second only to diamond in hardness but offers superior performance when grinding steels, where diamond wheels tend to break down due to chemical reactions at high temperatures.

Key Advantages of CBN Wheels:

-

High-Temperature Performance: CBN’s remarkable thermal resistance allows for high-speed grinding without risk of wheel degradation.

-

Extended Wheel Life: CBN wheels experience much lower wear rates compared to conventional abrasives like aluminum oxide, resulting in reduced downtime and maintenance.

-

Exceptional Toughness: The mechanical strength of CBN allows it to maintain cutting edges even under high-stress, high-heat conditions.

-

Superior Surface Finish: CBN wheels deliver high precision and finer finishes, crucial for parts like bearings, hardened tools, and turbine components.

-

Cost-Effectiveness: Despite a higher upfront cost, CBN wheels’ longevity often translates to lower overall operational costs.

Typical Applications:

-

Precision grinding of hardened steels

-

Sharpening tools and blades

-

Aerospace turbine components

-

Bearing component finishing

Diamond Wheels: The Choice for Hard Non-Ferrous Materials

Diamond wheels are best suited for grinding extremely hard, non-ferrous materials, such as:

-

Carbides

-

Ceramics

-

Glass

-

Stone

-

Composites

-

Semiconductor materials

While diamond is the hardest known substance, it tends to oxidize at elevated temperatures when used on ferrous metals, limiting its application to non-ferrous and heat-sensitive materials.

Key Advantages of Diamond Wheels:

-

Ultimate Hardness: Diamond wheels offer unmatched hardness, ideal for the most abrasive non-metallic materials.

-

Precision Machining: Perfect for industries like electronics and gemstone processing, where micro-tolerances and fine finishes are critical.

-

Efficiency in Material Removal: Enables faster grinding of hard materials, reducing machining time.

Typical Applications:

-

Grinding tungsten carbide tools

-

Precision machining of ceramics and semiconductor wafers

-

Grinding gemstones and composite materials

CBN vs. Diamond: A Quick Comparison

| Feature | CBN Wheels | Diamond Wheels |

|---|---|---|

| Material Suitability | Ferrous metals (steel, nickel alloys) | Non-ferrous hard materials (carbides, ceramics) |

| Thermal Resistance | Excellent; withstands high temperatures | Susceptible to oxidation at high temperatures |

| Hardness | Extremely hard; second only to diamond | Hardest known material |

| Durability | Longer life on ferrous materials | Exceptional on non-ferrous materials |

| Cost | Generally higher than conventional abrasives | Varies; cost-effective for non-ferrous grinding |

Why Choose CBN Wheels for Hard Ferrous Metals?

When it comes to grinding hardened steel, bearing components, or aerospace superalloys, CBN wheels offer a clear advantage:

-

Hardness and wear resistance far beyond traditional wheels

-

Superior thermal conductivity, minimizing heat-related damage

-

Long-lasting toughness, even at high grinding speeds

-

Precision surface finishes critical for high-performance parts

At Elitech Machine Tools, we recommend CBN wheels for applications where longevity, precision, and efficiency are non-negotiable.

Choosing the right grinding wheel means choosing better performance, lower operational costs, and a superior final product.

Partner with Elitech Machine Tools to find the best grinding solutions tailored to your industry needs.